What Was Plaster Recognized Long Ago as Plaster Art

Plaster is a building material used for the protective or decorative blanket of walls and ceilings and for moulding and casting decorative elements.[1] In English language, "plaster" usually means a material used for the interiors of buildings, while "return" normally refers to external applications.[2] Some other imprecise term used for the material is stucco, which is also often used for plasterwork that is worked in some style to produce relief ornamentation, rather than apartment surfaces.

The most mutual types of plaster mainly incorporate either gypsum, lime, or cement,[3] merely all work in a similar way. The plaster is manufactured as a dry powder and is mixed with water to grade a stiff but workable paste immediately before information technology is practical to the surface. The reaction with water liberates heat through crystallization and the hydrated plaster and so hardens.

Plaster can be relatively easily worked with metal tools or even sandpaper and can exist moulded, either on site or in advance, which are put in place with agglutinative. Plaster is not a strong material; it is suitable for finishing rather than load-bearing, and when thickly applied for ornament may require a hidden supporting framework, unremarkably in metal.

Forms of plaster have several other uses. In medicine, plaster orthopedic casts are still oft used for supporting set broken basic. In dentistry plaster is used to make dental models by pouring the material into dental impressions. Various types of models and moulds are made with plaster. In art, lime plaster is the traditional matrix for fresco painting; the pigments are applied to a thin wet top layer of plaster and fuse with it and then that the painting is actually in coloured plaster. In the aboriginal world, likewise equally the sort of ornamental designs in plaster relief that are still used, plaster was as well widely used to create large figurative reliefs for walls, though few of these take survived.

Types [edit]

Clay plaster [edit]

Dirt plaster is a mixture of dirt, sand and water with the addition of plant fibers for tensile force over forest lath.

Dirt plaster has been used since artifact. Settlers in the American colonies used dirt plaster on the interiors of their houses: "Interior plastering in the course of dirt antedated even the building of houses of frame, and must take been visible in the inside of wattle filling in those earliest frame houses in which …wainscot had not been indulged. Clay continued in the use long afterwards the adoption of laths and brick filling for the frame."[iv] Where lime was not available or easily accessible information technology was rationed or substituted with other binders. In Martin E. Weaver's seminal work he says, "Mud plaster consists of clay or earth which is mixed with water to give a "plastic" or workable consistency. If the dirt mixture is too plastic it will shrink, crack and misconstrue on drying. Information technology will also probably drop off the wall. Sand and fine gravels were added to reduce the concentrations of fine dirt particles which were the cause of the excessive shrinkage."[5] Straw or grass was added sometimes with the addition of manure.

In the Primeval European settlers' plasterwork, a mud plaster was used or more than unremarkably a mud-lime mixture.[5] McKee [4] writes, of a circa 1675 Massachusetts contract that specified the plasterer, "Is to lath and siele[six] the 4 rooms of the house between the joists overhead with a coat of lime and haire upon the clay; also to make full the gable ends of the house with bricks and plaster them with clay. five. To lath and plaster partitions of the house with clay and lime, and to fill, lath, and plaster them with lime and hair besides; and to siele and lath them overhead with lime; also to make full, lathe, and plaster the kitchen upward to the wall plate on every side. 6. The said Daniel Andrews is to detect lime, bricks, clay, stone, hair, together with laborers and workmen… ."[vii] Records of the New Haven colony in 1641 mention clay and hay besides equally lime and hair likewise. In German houses of Pennsylvania the use of clay persisted."[8]

Clay plaster base coat on split oak lath held in place with harbinger and manure, covered with a lime plaster top coat, Onetime Economy Village, Pennsylvania (1827)

Old Economy Village is 1 such German settlement. The early Nineteenth-Century utopian village in nowadays-24-hour interval Ambridge, Pennsylvania, used dirt plaster substrate exclusively in the brick and wood frame high architecture of the Banquet Hall, Great House and other large and commercial structures as well every bit in the brick, frame and log dwellings of the order members. The use of dirt in plaster and in laying brickwork appears to have been a common practice at that time not just in the construction of Economic system hamlet when the settlement was founded in 1824. Specifications for the construction of, "Lock keepers houses on the Chesapeake and Ohio Canal, written about 1828, crave stone walls to exist laid with clay mortar, excepting 3 inches on the exterior of the walls…which (are) to be adept lime mortar and well pointed."[9] The choice of clay was because of its depression cost, simply also the availability. At Economic system, root cellars dug under the houses yielded clay and sand (stone), or the nearby Ohio river yielded washed sand from the sand bars; and lime outcroppings and oyster shell for the lime kiln. Other required building materials were too sourced locally.

The surrounding forests of the new village of Economy provided straight grain, old-growth oak trees for board.[10] Hand dissever board starts with a log of straight grained woods of the required length. The log is split into quarters then smaller and smaller bolts with wedges and a sledge. When minor enough, a froe and mallet were used to separate away narrow strips of lath - unattainable with field trees and their many limbs. Farm animals pastured in the fields cleared of copse provided the hair and manure for the float glaze of plaster. Fields of wheat and grains provided harbinger and other grasses for binders for the clay plaster. Merely there was no uniformity in dirt plaster recipes.

Straw or grass was added sometimes with the addition of manure providing fiber for tensile strength as well every bit poly peptide adhesive. Proteins in the manure act equally binders. The hydrogen bonds of proteins must stay dry to remain strong, and so the mud plaster must be kept dry out.[xi] With braced timber-framed structures clay plaster was used on interior walls and ceilings also equally outside walls as the wall cavity and exterior cladding isolated the clay plaster from moisture penetration. Application of dirt plaster in brick structures risked h2o penetration from failed mortar joints on the exterior brick walls. In Economy Village, the rear and middle wythes of brick dwelling walls are laid in a clay and sand mortar with the forepart wythe bedded in a lime and sand mortar to provide a weather proof seal to protect from h2o penetration. This allowed a rendering of clay plaster and setting glaze of thin lime and fine sand on exterior-walled rooms.

Lime setting-glaze on clay plaster with straw binder. Applied to hand-split board over a timber framed wall of a brick family firm at Erstwhile Economy Village, Pennsylvania

Split lath was nailed with square cut board nails, one into each framing member. With hand divide board the plasterer had the luxury of making lath to fit the cavity existence plastered. Lengths of lath two to six human foot are not uncommon at Economic system Village. Hand split lath is non uniform like sawn board. The straightness or waviness of the grain affected the thickness or width of each lath, and thus the spacing of the lath. The clay plaster rough coat varied to cover the irregular lath. Window and door trim every bit well every bit the mudboard (baseboard) acted as screeds. With the variation of the board thickness and utilize of coarse harbinger and manure, the dirt glaze of plaster was thick in comparison to later lime-only and gypsum plasters. In Economy Village, the lime acme coats are sparse veneers oftentimes an eighth inch or less attesting to the scarcity of limestone supplies there.

Dirt plasters with their lack of tensile and compressive strength fell out of favor every bit industrial mining and applied science advances in kiln product led to the exclusive use of lime and then gypsum in plaster applications. Withal, dirt plasters still be later hundreds of years clinging to split up lath on rusty foursquare nails. The wall variations and roughness reveal a manus-made and pleasing textured culling to machine-fabricated modern substrate finishes. Simply clay plaster finishes are rare and fleeting. Co-ordinate to Martin Weaver, "Many of Due north America'south historic building interiors…are all too oft…one of the showtime things to disappear in the frenzy of demolition of interiors which has unfortunately come to be a mutual companion to "heritage preservation" in the guise of building rehabilitation."[5]

Gypsum plaster (plaster of Paris) [edit]

Gypsum plaster,[12] also known as plaster of Paris,[13] is a white powder consisting of calcium sulphate hemihydrate. The natural form of the compound is the mineral bassanite.[14] [15]

Etymology [edit]

The name "plaster of Paris" came from the fact that it was originally made by heating gypsum from a large deposit at Montmartre, a loma in the north end of Paris.[thirteen] [16] [17]

Chemistry [edit]

Gypsum plaster, gypsum pulverization, or plaster of Paris, is produced by heating gypsum to virtually 120–180 °C (248–356 °F) in a kiln:[18] [thirteen]

- heat (released equally steam).

Plaster of Paris has a remarkable belongings of setting into a hard mass on wetting with h2o.

Plaster of Paris is stored in moisture-proof containers, because the presence of moisture can cause wearisome setting of plaster of Paris past bringing about its hydration, which will arrive useless after some time.[nineteen]

When the dry plaster pulverisation is mixed with h2o, it rehydrates over time into gypsum. The setting of plaster slurry starts about ten minutes afterwards mixing and is complete in virtually 45 minutes. The setting of plaster of Paris is accompanied by a slight expansion of volume due to which it is used in making casts for statues, toys, etc.[xix] The initial matrix consists generally of orthorhombic crystals - the kinetic product. Over the next 72 hours the rhombic crystals give way to an interlocking mass of monoclinic crystal needles and the plaster increases in hardness and gains strength.[20] If plaster or gypsum is heated to between 130 °C, (266 °F) and 180 °C (350°F), hemihydrate is formed, which will also re-form as gypsum if mixed with water.[21] [22]

On heating to 180 °C (350°F), the about water-free form, called γ-anhydrite (CaSOiv·nH2O where n = 0 to 0.05) is produced. γ-Anhydrite reacts slowly with h2o to return to the dihydrate state, a holding exploited in some commercial desiccants. On heating to a higher place 250 °C (480°F), the completely anhydrous form called β-anhydrite or dead burned plaster is formed.[nineteen] [22]

Uses of gypsum plaster [edit]

- for making surfaces like the walls of a house smoothen before painting them and for making ornamental designs on the ceilings of houses and other buildings.[19] (come across Plaster In decorative architecture)

- for making toys, decorative materials, cheap ornaments, cosmetics, black-board, chalk and casts for statue.[19]

- a burn-proofing cloth.[nineteen] (see Plaster in Fire protection)

- an orthopedic cast is used in hospitals for setting fractured basic in the right position to ensure correct healing and avert nonunion. It keeps the fractured os straight. This utilize is based on the fact that when plaster of Paris is mixed with a proper quantity of h2o and applied around the fractured limbs it sets into a hard mass, In this way it keeps the bone joints in a fixed position. It is also used for making casts in dentistry.[19] (run across Plaster in Medicine)

- chemistry laboratory for sealing air-gaps in apparatus when air-tight system is required.[nineteen]

Lime plaster [edit]

Lime plaster is a mixture of calcium hydroxide and sand (or other inert fillers). Carbon dioxide in the atmosphere causes the plaster to set by transforming the calcium hydroxide into calcium carbonate (limestone). Whitewash is based on the same chemistry.

To make lime plaster, limestone (calcium carbonate) is heated in a higher place approximately 850 °C (1600°F) to produce quicklime (calcium oxide). Water is and then added to produce slaked lime (calcium hydroxide), which is sold equally a wet putty or a white powder. Additional water is added to grade a paste prior to utilise. The paste may exist stored in airtight containers. When exposed to the temper, the calcium hydroxide very slowly turns dorsum into calcium carbonate through reaction with atmospheric carbon dioxide, causing the plaster to increase in strength.

Lime plaster was a common building textile for wall surfaces in a procedure known as lath and plaster, whereby a series of wooden strips on a studwork frame was covered with a semi-dry plaster that hardened into a surface. The plaster used in most lath and plaster structure was mainly lime plaster, with a cure time of almost a calendar month. To stabilize the lime plaster during curing, small amounts of plaster of Paris were incorporated into the mix. Considering plaster of Paris sets quickly, "retardants" were used to ho-hum setting fourth dimension enough to allow workers to mix big working quantities of lime putty plaster. A modern course of this method uses expanded metal mesh over wood or metallic structures, which allows a great freedom of design as it is adaptable to both elementary and compound curves. Today this building method has been partly replaced with drywall, also composed mostly of gypsum plaster. In both these methods, a primary advantage of the textile is that information technology is resistant to a fire inside a room and so tin aid in reducing or eliminating structural damage or destruction provided the fire is promptly extinguished.

Lime plaster is used for frescoes, where pigments, diluted in h2o, are applied to the yet wet plaster.

The states and Iran are the chief plaster producers in the world.[ commendation needed ]

Cement plaster [edit]

Cement plaster is a mixture of suitable plaster, sand, Portland cement and h2o which is ordinarily applied to masonry interiors and exteriors to reach a smooth surface. Interior surfaces sometimes receive a final layer of gypsum plaster. Walls constructed with stock bricks are normally plastered while face up brick walls are not plastered. Various cement-based plasters are also used every bit proprietary spray fireproofing products. These ordinarily use vermiculite as lightweight aggregate. Heavy versions of such plasters are also in use for exterior fireproofing, to protect LPG vessels, pipe bridges and vessel skirts.

Cement plaster was kickoff introduced in America around 1909 and was often chosen by the generic proper name adamant plaster subsequently a prominent manufacturer of the fourth dimension. The advantages of cement plaster noted at that time were its strength, hardness, quick setting time and immovability.[23]

Heat-resistant plaster [edit]

Heat-resistant plaster is a building material used for coating walls and chimney breasts and for utilise as a fire barrier in ceilings. Its purpose is to replace conventional gypsum plasters in cases where the temperature can get likewise high for gypsum plaster to stay on the wall or ceiling.

Applications [edit]

In decorative compages [edit]

-

Early 19th Century plasterer at work - painting by John Cranch (1751–1821)

-

Face up plaster casting bandage application

Plaster may also be used to create circuitous detailing for use in room interiors. These may be geometric (simulating wood or stone) or naturalistic (simulating leaves, vines, and flowers). These are as well often used to simulate wood or stone detailing establish in more substantial buildings.

In modern days this cloth is also used for False Ceiling. In this, the powder form is converted in a canvas grade and the canvas is so attached to the basic ceiling with the help of fasteners. It is done in various designs containing various combinations of lights and colors. The common use of this plaster can be seen in the construction of houses. Post-construction, direct painting is possible (which is usually seen in French compages), but elsewhere plaster is used. The walls are painted with the plaster which (in some countries) is nothing but calcium carbonate. Later on drying the calcium carbonate plaster turns white and then the wall is ready to exist painted. Elsewhere in the world, such as the UK, ever finer layers of plaster are added on top of the plasterboard (or sometimes the brick wall directly) to give a smooth brown polished texture ready for painting.

Art [edit]

Instance of a stenciled plaster design

Landscape paintings are commonly painted onto a plaster secondary support. Some, like Michelangelo's Sistine Chapel ceiling, are executed in fresco, pregnant they are painted on a sparse layer of moisture plaster, called intonaco; the pigments sink into this layer so that the plaster itself becomes the medium holding them, which accounts for the excellent durability of fresco. Additional work may exist added a secco on summit of the dry plaster, though this is generally less durable.

Plaster (frequently called stucco in this context) is a far easier cloth for making reliefs than stone or woods, and was widely used for big interior wall-reliefs in Egypt and the Well-nigh E from artifact into Islamic times (latterly for architectural ornamentation, every bit at the Alhambra), Rome, and Europe from at least the Renaissance, every bit well as probably elsewhere. Even so, information technology needs very good conditions to survive long in unmaintained buildings – Roman decorative plasterwork is mainly known from Pompeii and other sites buried by ash from Mount Vesuvius.

Plaster may exist bandage directly into a damp dirt mold. In creating this slice molds (molds designed for making multiple copies) or waste molds (for single use) would be made of plaster. This "negative" image, if properly designed, may exist used to produce dirt productions, which when fired in a kiln become terra cotta building decorations, or these may exist used to create cast concrete sculptures. If a plaster positive was desired this would be synthetic or cast to class a durable image artwork. Equally a model for stonecutters this would exist sufficient. If intended for producing a statuary casting the plaster positive could exist further worked to produce smooth surfaces. An reward of this plaster image is that it is relatively cheap; should a patron approve of the durable paradigm and be willing to conduct farther expense, subsequent molds could exist made for the creation of a wax paradigm to be used in lost wax casting, a far more expensive process. In lieu of producing a statuary paradigm suitable for outdoor use the plaster image may be painted to resemble a metallic epitome; such sculptures are suitable only for presentation in a weather-protected environment.

Plaster expands while hardening and so contracts slightly just earlier hardening completely. This makes plaster excellent for use in molds, and it is often used as an creative cloth for casting. Plaster is also ordinarily spread over an armature (class), fabricated of wire mesh, textile, or other materials; a procedure for adding raised details. For these processes, limestone or acrylic based plaster may be employed, known every bit stucco.[ citation needed ]

Products composed mainly of plaster of Paris and a small amount of Portland cement are used for casting sculptures and other art objects as well as molds. Considerably harder and stronger than straight plaster of Paris, these products are for indoor utilise only every bit they quickly degrade in the rain.

Funeral processes [edit]

Plaster is used by many morticians and funeral home directors to recreate destroyed tissue, reconnect severed limbs to corpses, and to fill up wounds sustained during the incident that caused the death.

Medicine [edit]

Plaster is widely used as a support for broken basic; a bandage impregnated with plaster is moistened and and so wrapped effectually the damaged limb, setting into a close-fitting still hands removed tube, known as an orthopedic cast.

Plaster is too used in training for radiotherapy when fabricating individualized immobilization shells for patients. Plaster bandages are used to construct an impression of a patient's head and neck, and liquid plaster is used to make full the impression and produce a plaster bust. The transparent material polymethyl methacrylate (Plexiglas, Perspex) is so vacuum formed over this bust to create a clear face mask which will hold the patient's caput steady while radiation is being delivered.[ citation needed ]

In dentistry, plaster is used for mounting casts or models of oral tissues. These diagnostic and working models are usually made from dental stone, a stronger, harder and denser derivative of plaster which is manufactured from gypsum under pressure. Plaster is also used to invest and flask wax dentures, the wax existence later on removed by "burning out," and replaced with flowable denture base textile. The typically acrylic denture base of operations and so cures in the plaster investment mold. Plaster investments tin withstand the high rut and pressure level needed to ensure a rigid denture base. Moreover, in dentistry at that place are 5 types of gypsum products depending on their consistency and uses: 1) impression plaster (blazon 1), ii) model plaster (type 2), dental stones (types 3, iv and 5)[ citation needed ]

In orthotics and prosthetics, plaster bandages traditionally were used to create impressions of the patient's limb (or rest). This negative impression was then, itself, filled with plaster of Paris, to create a positive model of the limb and used in fabricating the terminal medical device.

In addition, dentures (false teeth) are made past first taking a dental impression using a soft, pliable fabric that can be removed from around the teeth and gums without loss of fidelity and using the impression to creating a wax model of the teeth and gums. The model is used to create a plaster mold (which is heated then the wax melts and flows out) and the denture materials are injected into the mold. After a curing menses, the mold is opened and the dentures are cleaned upward and polished.

Burn protection [edit]

Plasters have been in utilise in passive burn protection, as fireproofing products, for many decades.

The finished plaster releases h2o vapor when exposed to flame, acting to slow the spread of the fire, for equally much equally an 60 minutes or two depending on thickness. It also provides some insulation to retard heat period into structural steel elements, that would otherwise lose their strength and collapse in a burn down. Early versions of these plasters have used asbestos fibres, which have by now been outlawed in industrialized nations and take caused significant removal and re-coating work. More modern plasters fall into the following categories:

- fibrous (including mineral wool and glass fiber)

- cement mixtures either with mineral wool or with vermiculite

- gypsum plasters, leavened with polystyrene beads, as well equally chemic expansion agents to subtract the density of the finished product

One differentiates betwixt interior and outside fireproofing. Interior products are typically less substantial, with lower densities and lower toll. Outside products have to withstand more than extreme fire and other environmental weather condition. Exterior products are as well more likely to exist attractively tooled, whereas their interior cousins are unremarkably but sprayed in place. A rough surface is typically forgiven within of buildings every bit dropped ceilings ofttimes hibernate them. Exterior fireproofing plasters are losing ground to more than plush intumescent and endothermic products, simply on technical merit. Trade jurisdiction on unionized construction sites in North America remains with the plasterers, regardless of whether the plaster is decorative in nature or is used in passive fire protection. Cementitious and gypsum based plasters tend to be endothermic. Fireproofing plasters are closely related to firestop mortars. Nearly firestop mortars tin be sprayed and tooled very well, due to the fine item work that is required of firestopping, which leads their mix designers to use concrete admixtures, that enable easier tooling than common mortars.

3D printing [edit]

Powder bed and inkjet caput 3D printing is ordinarily based on the reaction of gypsum plaster with h2o, where the h2o is selectively applied past the inkjet head.

Gallery [edit]

-

Figure of a woman; fifth century; painted plaster; top: 38.4 cm (15"), width: fourteen.seven cm (6"), depth: 9.6 cm (4"); Metropolitan Museum of Art

-

Seated Voltaire; by Jean-Antoine Houdon; 1778; plaster, tinted to imitate terracotta; overall: 35.six x 14.half-dozen x 20 cm (xiv" 10 five¾" x viii"); Metropolitan Museum of Art

-

Young girl; first modeled: 1779–1780; plaster; height: 36.8 cm (14½"); Metropolitan Museum of Art

-

Nymph; 1805–1810; plaster; height: 155.six cm (five'1¼"); Metropolitan Museum of Art

-

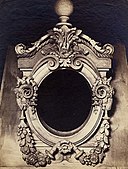

Photo of a plaster model of an ornamental oeil-de-boeuf for the new Louvre; circa 1856; Metropolitan Museum of Art

-

Jupiter and the Sphinx; 1868; tinted plaster; 116.8 × 112.i × lx.3 cm (3'x" x three'viii" x 1'xi¾"); Metropolitan Museum of Art

Safety issues [edit]

The chemic reaction that occurs when plaster is mixed with water is exothermic. When plaster sets, it tin can reach temperatures of more 60 °C (140°F) and, in large volumes, tin burn down the skin. In Jan 2007, a secondary school student in Lincolnshire, England sustained third-degree burns afterward encasing her easily in a saucepan of plaster as part of a schoolhouse art projection. The burns were and so severe she required amputation of both her thumbs and vi of her fingers.[24]

Some variations of plaster that comprise powdered silica or asbestos may present health hazards if inhaled. Asbestos is a known irritant when inhaled and can cause cancer, especially in people who smoke,[25] [26] and inhalation can also crusade asbestosis. Inhaled silica tin can cause silicosis and (in very rare cases) can encourage the evolution of cancer.[27] Persons working regularly with plaster containing these additives should have precautions to avert inhaling powdered plaster, cured or uncured. (Note that asbestos is rarely used in modern plaster formulations considering of its carcinogenic[28] effects.)

People tin be exposed to plaster of Paris in the workplace by breathing it in, swallowing information technology, peel contact, and centre contact. The Occupational Safe and Health Assistants (OSHA) has set the legal limit (permissible exposure limit) for plaster of Paris exposure in the workplace every bit 15 mg/yardiii total exposure and 5 mg/1000iii respiratory exposure over an eight-hour workday. The National Establish for Occupational Safety and Health (NIOSH) has set a Recommended exposure limit (REL) of 10 mg/m3 total exposure and 5 mg/yard3 respiratory exposure over an 8-hour workday.[29]

See besides [edit]

- Anhydrite

- Bughole, a structural defect in physical or plaster

- Calcium Sulfate

- Cast Courts (Victoria and Albert Museum)

- Clay panel

- Diapalma

- Harl, a lime-plaster outside stop used on buildings in Scotland

- Hy-Rib

- International Union of Bricklayers and Allied Craftworkers

- Intumescent, a burn down-protection additive in some plasters

- Intonaco, the plaster coat on and in which a fresco is painted

- Articulation chemical compound

- Lath and plaster, a construction method

- Opus albarium, a marble plaster used in fine decorative work

- Passive fire protection

- Parge coat, a thin layer of plaster added to an exterior wall

- Pargeting, a decorative or waterproofing plastering applied to building walls

- Phosphogypsum

- Plasterwork

- Polished plaster

- Ready-mix lightweight joint chemical compound

- Roughcast, an outside finish used on buildings

- Stucco

- Tadelakt, a waterproof plaster made by ramming, polishing, and staining with soap

- Wattle and daub, a construction method

- Paigah Tombs, intricate stucco work made in 19th-century Hyderabad, India

- Yeseria, a style of plaster sculpture used historically in the Middle E, Magreb, and Iberian Peninsula

References [edit]

- ^ Plaster. In: Weyer, Angela; Roig Picazo, Pilar; Popular, Daniel; Cassar, JoAnn; Özköse, Aysun; Vallet, Jean-Marc; Srša, Ivan, eds. (2015). EwaGlos. European Illustrated Glossary Of Conservation Terms For Wall Paintings And Architectural Surfaces. English Definitions with translations into Bulgarian, Croatian, French, German, Hungarian, Italian, Polish, Romanian, Castilian and Turkish. Petersberg: Michael Imhof. p. 50.

- ^ Henry, Alison; Stewart, John, eds. (2011). English Heritage. Applied Edifice Conservation. Mortars, Renders & Plasters. Farnham / Burlington: Ashgate. p. 87.

- ^ Franz Wirsching "Calcium Sulfate" in Ullmann's Encyclopedia of Industrial Chemistry, 2012 Wiley-VCH, Weinheim. doi:x.1002/14356007.a04_555

- ^ a b McKee, Harvey J. (2017). An Introduction to Early American Masonry, Stone, Brick, Mortar and Plaster. Springfield, IL: Association for Preservation Applied science International. p. 81. ISBN978-0-9986347-0-8.

- ^ a b c Weaver, Martin E. (1997). Conserving Buildings, A Manual of Techniques and Materials, Revised Edition. New York: Preservation Press. p. 149. ISBN978-0-471-50944-eight.

- ^ Richardson, Charles (1846). "A New Dictionary of the English language Language". Retrieved 4 December 2017.

- ^ Cousins, Frank; Riley, Phil Yard. (1919). The Colonial Compages of Salem. Boston: Petty Brown and Company. pp. 39–forty.

- ^ Kimbal, Sidney Fiske (1922). Domestic Architecture of American Colonies and the Early Republic. New York: Scribner'south Sons. p. 30.

- ^ McKee, Harley (2017). An Introduction to Early American Masonry, Rock, Brick, Mortar and Plaster. Springfield, IL: Association of Preservation Technology. p. 61.

- ^ Tree-ring dating study, Geology Department, Wooster College, Wooster, Ohio. Study commissioned by Dennis Lapic, 2009. The report showed straight grained logs with get-go year of growth from 1662 to 1748, feature of trees of a virgin forest.

- ^ Chen, S. (nineteen Dec 2003). "Value-Added Chemicals from Beast Manure". CiteSeerXx.i.i.463.4548.

- ^ "Gypsum plaster | building material". Encyclopedia Britannica . Retrieved 2020-10-09 .

- ^ a b c "plaster of paris | Definition, Uses, & History". Encyclopedia Britannica . Retrieved 2020-ten-09 .

- ^ "Bassanite".

- ^ "List of Minerals". 21 March 2011.

- ^ Szostakowski, B.; Smitham, P.; Khan, W.S. (2017-04-17). "Plaster of Paris–Short History of Casting and Injured Limb Immobilzation". The Open up Orthopaedics Journal. 11: 291–296. doi:x.2174/1874325001711010291. ISSN 1874-3250. PMC5420179. PMID 28567158.

- ^ plaster of Paris definition. Webster'south New Globe College Lexicon at YourDictionary.com.

- ^ Staff. "CaSO4, ½ H2O". LaFargePrestia. Archived from the original on November 20, 2008. Retrieved 27 November 2008.

- ^ a b c d east f g h Singh, Lakhmir; Kaur, Manjit (2019). Science for Class ten Office-2 Chemistry. South. Chand. ISBN978-9352837892.

- ^ Schmidt, V.E.; Somerset, J.H.; Porter, R.E. (1973). "Mechanical Backdrop of Orthopeadic Plaster Bandages". Periodical of Biomechanics. Elsevier. 6 (ii): 173–185. doi:10.1016/0021-9290(73)90086-9. PMID 4693147.

Hardening phase of plaster of paris is basically a crystalline change in which orthorhombic form of gypsum converts into monoclinic course of gypsum.

- ^ Deer, Howie, & Zussman. "An Introduction to the Rock Forming Minerals." Pearson Instruction Limited, England, 2nd Edition, 1992, Folio 614. ISBN 0-582-30094-0

- ^ a b Posnjak, East. (1938), The System CaSO4–H2O (PDF), pp. 247–,

The long experience in the manufacture of plaster of Paris presents a consistent record that whenever gypsum is heated at non too high a temperature–usually about 130°–the product formed is invariably the hemihydrate ; and further, that if the temperature is permitted to become considerably higher, the product becomes "dead burned," it has then been converted into anhydrite.

- ^ Roberts, Isaac Phillips. The farmstead; the making of the rural home and the lay-out of the farm,. seventh ed. New York: Macmillan Co., 1914. Print. 188.

- ^ "Amputation later on art class burns". BBC News. 2007-03-23. Retrieved 2010-05-22 .

- ^ Hammond, EC; Garfinkel, L; Seidman, H; Lew, EA (Dec 1976). ""Tar" and nicotine content of cigarette smoke in relation to decease rates". Environmental Research. 12 (3): 263–74. Bibcode:1976ER.....12..263H. doi:ten.1016/0013-9351(76)90036-0. PMID 1001298.

- ^ Saracci, R (1987). "The interactions of tobacco smoking and other agents in cancer etiology". Epidemiologic Reviews. ix: 175–93. doi:ten.1093/oxfordjournals.epirev.a036301. PMID 3315716.

- ^ Soutar, CA; Robertson, A; Miller, BG; Searl, A; Bignon, J (January 2000). "Epidemiological show on the carcinogenicity of silica: factors in scientific judgement". The Annals of Occupational Hygiene. 44 (i): iii–14. doi:x.1093/annhyg/44.1.three. PMID 10689755.

- ^ Hazardous chemicals: second written report on the inquiry into chancy chemicals. Canberra : Australia: Australian Authorities Publications Service. 1982. OCLC 66780789.

The carcinogenic activity of asbestos derives from its morphology, not its chemical nature

- ^ "CDC - NIOSH Pocket Guide to Chemical Hazards - Plaster of Paris". www.cdc.gov . Retrieved 2015-11-21 .

External links [edit]

| | Expect upwards plaster in Wiktionary, the free dictionary. |

gonzalezwhadming1966.blogspot.com

Source: https://en.wikipedia.org/wiki/Plaster

0 Response to "What Was Plaster Recognized Long Ago as Plaster Art"

Post a Comment