Easy Way to Make a Concrete Shower Pan

Our new shower – for the duration of this trip

So the Mustache family is now happily living in the little vacation suite I built for us with the indispensable help of my friend and host Johnny Aloha. There are still some finishing touches to add (including paint), but for the most part everything works now.

The nicest part of this place is the shower, which you can see there in the picture on the left. Ooh, ahh.. looks cozy, doesn't it? Well I like it, anyway, and I wanted to build something that would serve as a centerpiece to this future rental unit that would anchor it in the luxury market and thus allow it to earn higher rents forever.

The cool part is, it didn't really cost much to build. Those floor-to-ceiling travertine tiles, dark slate, river rock floor stones, and even the handle and valve set were all found on Craigslist at a deep discount. The shampoo nook which keeps your wife's shaving razors from messing with your personal space is just a few extra cuts on the tile saw. And the sloped pan that allows water to run to the drain was custom made from plain old concrete and masonry mix, at a fraction of the cost of even an off-the-shelf plastic showerpan. And yet, the whole thing took only a few days of work to create from a blank plywood-and-studs slate (which in turn I made from the even blanker slate of what was formerly unused space in their carport).

A fancy shower can add $10,000 or more to the value of a house in a nice area. It is also very pleasant to use even if you're not planning to sell your house – I built a similar shower in my own house and we've enjoyed it very much for the past several years. But if you ask a bathroom contractor to make you one of these things, you'll often get a quote of $5,000 or more, and as a result, most of us are stuck showering in metal bathtubs or plastic showerpans framed by old moldy white tiles.

The key to this whole deal is a feature called the "poured showerpan". It's an elusive black-ops creation that almost nobody knows how to build in this country, which is why you see so many plastic showerpans out there. Some professional tile installers can do it, but they will charge you a fortune, and it may still not come out the way you want it. But once you unlock its secrets, you are free to build shower pans in any shape and size, at a surprisingly low cost (about 60 bucks including the drain and the waterproofing*). And today I will show you how to make one.

The basic idea is this: we're making an absolutely waterproof concrete bowl with a drain in the middle.

Look for a two piece drain like this. This type is designed to clamp around a plastic showerpan, but it works well for our purposes (you just won't need the rubber ring) (image credit/Hand Model: Mike)

Usually there will be a raised "curb" at the edge, and a nice tile or stone surface above the concrete. After you finish the bowl, tile it, and grout the tiles, you move on up to tile the rest of the shower walls. But it all starts with the poured showerpan.

Step 1: The Curb

The easiest way to go about this is to make the curb first. This involves creating a wooden form and filling it with concrete. I usually make these things 5″ tall and 4″ thick, so you simply cut two 5″ boards to length, screw them to the floor and walls as needed, and be sure there is a 4″ space between them.

Here's an example of an irregularly shaped angle form I made last year to squeeze a shower into the small bathroom of The Foreclosure Project:

An angled form. Reinforced with screws and wire.

Note that for extra strength in this case, I put some large 4″ screws into the floor at each joint, and ran some steel reinforcing wire along the length of the form's center, to create more tensile strength (and thus crack resistance) in the finished form. This is not usually necessary, I just find it really fun to make strong concrete things. The black material at the bottom is roofing paper – just to isolate the concrete from the plywood so the moisture from the wet concrete would not wick out into the floor. A general good practice for concrete over wood.

In the most recent shower, our curb looked like this:

Drain is in place – top surface about 2″ above the plywood.

If you're also doing your own drain plumbing, you'll want the drain pipe to end just about flush with the plywood floor, so that when you glue on the shower drain, it is about 2″ above the floor. Thus, when we pour the concrete at the next step, the minimum thickness will be 2″.

Step 2: Pouring the Sloped Concrete

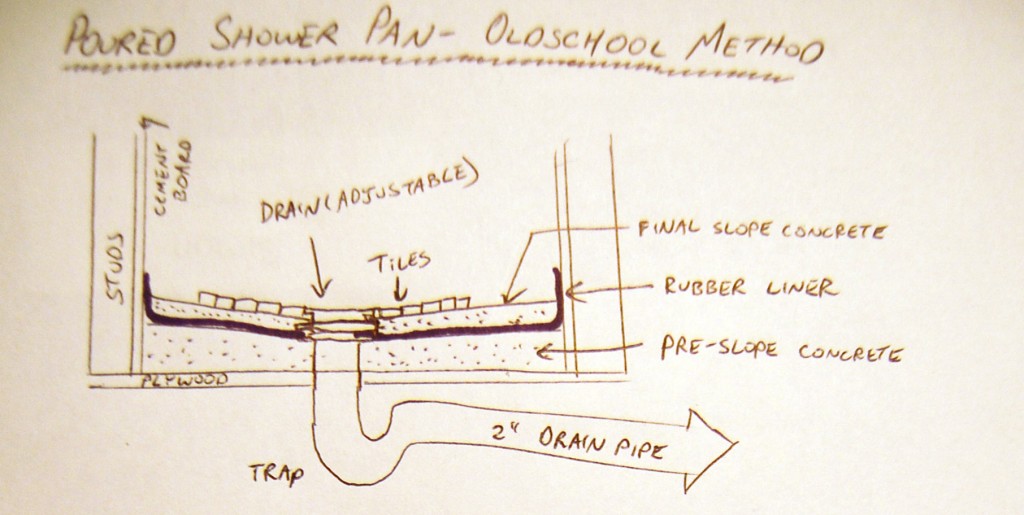

This is the part where things get exciting, and this article will hopefully save DIY shower builders some time and money. In the olden days (and still today for the most part), poured showerpans were done in three steps: the poured pre-slope, the rubber liner, then the poured top slope. It looked roughly like this:

Old showerpan method – concrete, rubber, concrete, tile.

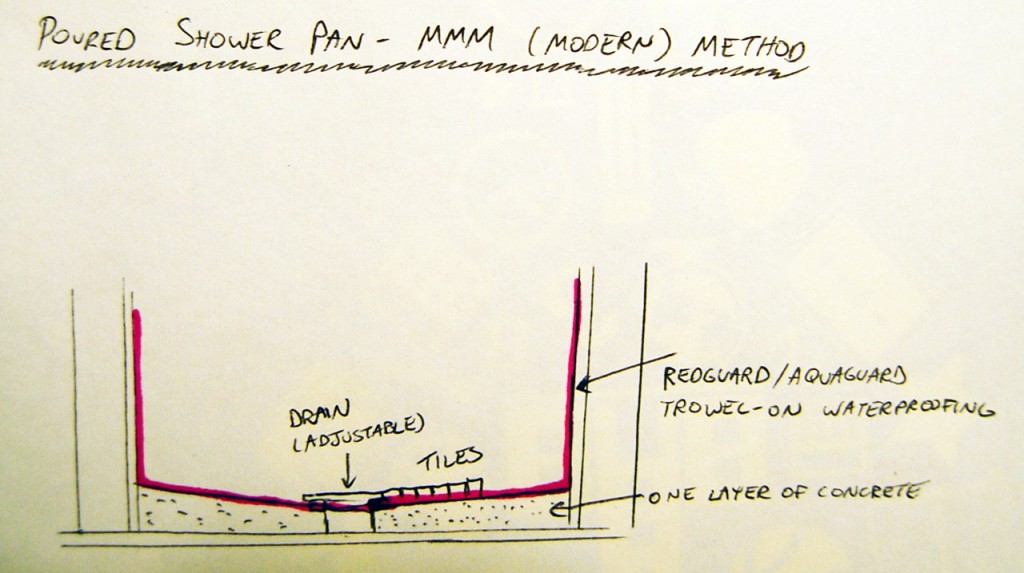

The thing is, the old method has not been updated to reflect a more recent invention: trowel-on waterproofing materials like Redguard and Aquaguard. This stuff is basically liquid rubber in a bucket, and it overcomes the old shortcoming of rubber by combining full waterproofing with a surface to which you can stick tiles directly. With the new technology, you can skip one layer of concrete, and you end up with this:

Easier new showerpan method: concrete, redguard, tile.

Note that this method is something I more or less invented for myself by puzzling through the product's poorly written technical documentation and trying it out. The tile installers I know still do things the old way and some might scoff at the innovation. But I've built at least 20 showers like this now, and I can still look at the oldest one from below and verify perfectly dry wood beneath- no leaks. It would be virtually impossible for this designnot to be watertight, as long as you do tidy work.

Now that you understand the basics, let's check out a couple of action pictures to show the pouring, forming, and waterproofing in detail.

Preparation:

The top of your drain should be about 2″ off the floor. To create a uniform slope, use a ruler or level to draw a line all around the perimeter of the showerpan that is about 2.75″ off the floor. This will provide a nice 3/4″ slope to allow water to flow down into the drain.

The Mix:

You'll want a fairly dry (almost crumbly) mix of cement. But not regular concrete with gravel aggregate in it, here we usemason's mix, which is just portland cement and sand – the same stuff used for brick mortar. Available right next to regular bags of concrete in the store. About three 80lb (36 kg) bags will do a 32″x48″ shower.

Spreading it around:

Mix the cement outside in a wheelbarrow one bag at a time, and carry it in to the house in a 5 gallon bucket. Dump it into your future shower, and it will look like this:

Dump it in, spread it around. Note that the drain's removable/adjustable top is removed for this step. But cover the remaining part of the drain with tape, lest you get concrete into the trap!

From here on in, it is all smoothing – use a variety of straight edges to scrape and smooth the concrete, adding more bags of it until you end up with a nice smooth bowl:

When it starts looking smooth, I shine a flashlight horizontally across the surface to higlight any bumps and waves, which can be scraped out and re-smoothed:

And finally, when everything is ready to retire for the night, it should look roughly like this:

Here's a completed pan, still wet. All the tools involved are shown too.

Step 3: Final Waterproofing

After the concrete cures (technically 28 days but it's a half-life process so it's almost done in less than a week), you have a solid chunk of smooth concrete that in theory will already drain water straight into the drain. But we want even better waterproofing, and thus you are ready for the Redguard step. This goes right over the concrete, over the plastic edge of the drain, and up the walls a few feet. Then you can screw in the final drain top part, which you crank down to align with your finished tiles, like this:

This is the latest Hawaiian shower, waterproofed and ready for floor tile.

After this dries, you're back to a standard tile job: Do the floor and grout it first (for greatest waterproofing), then work your way up the walls the next day. I don't have space left in this article to explain the entire art of tiling a shower, but perhaps I'll have a chance to work with you in person on one of these things someday.

The Poured Showerpan may seem like an elusive and tricky task, but the whole thing is about 4 hours of work from start to finish once you work out the kinks (and still under 8 even the first time). After that, it will take you another 8-16 hours to tile and grout the remainder of the shower and its curb. For many DIY home renovators, learning this skill it is an investment with enormous returns.

If this shower makes our new rental worth $100 more per month, it is providing equivalent cashflow to a $30,000 investment yielding 4% after inflation. Just another example of the wonderful synergy between practical skills and financial independence.

*The 60 bucks is just for the showerpan, of course. Then you'll add about 12 square feet of floor tile, 75 sqft of cementboard and wall tile, tile adhesive, grout, and a valve set. The total can still be only a few hundred dollars if you shop well (ours was even less, due to Craigslist).

gonzalezwhadming1966.blogspot.com

Source: https://www.mrmoneymustache.com/2012/12/21/how-to-make-a-relatively-sweet-shower-cheap/

0 Response to "Easy Way to Make a Concrete Shower Pan"

Post a Comment